This step was challenging simply because we didn't have a manual that provided hole locations. Unfortunately, we didn't even have a dummy driver's seat so, we had to forecast where components and driver seating position would eventually be. We mocked-up the dash board temporarily and used a shop stool so we could visualize alignment of the steering column and pedals. We then checked inside and outside clearances and it was immediately obvious that there were two conflicts. We didn't want the master cylinder to be right over and behind our left front tire, and the brake pedal and steering column were in conflict. After much hand-wringing, we decided to position the steering column first, and engineer an off-set brake pedal so we could mount the master cylinder inboard of the front left tire's range of motion. Once we were past these decisions, it was also easy to target the gas pedal. We would provide our hole locations, but we recommend everyone go through this exercise themselves since every project will be different. We used a hole saw for the master cylinder piston. The throttle cable will be installed at a later date.

Step 12: Install Steering Column

The donor's steering column was way too long to fit in the Gorilla. Urban Gorilla supplied us with a 1990 Celebrity steering column with the shifter removed, and a disabled neutral safety switch. This would allow the steering column to work with the keys removed and borrowing the new B&M Hammer Shifter's neutral safety switch feature. Now we should point out that the steering column and shaft are two separate assemblies, one installs on the inside and penetrates the firewall. The second assembly is the Borg steering shaft and installs outside under the hood.

Before we could install the steering column inside the truck, we had to take our 36" Borg steering shaft and carefully turn the front tires to establish the best angle of clearance between the column and tires. From here we established the firewall hole for the column. We had to do all of these steps to target the column-firewall hole in Step 11 above to aid in pedal targeting. Back inside the truck we verified that the column would provide room for the brake pedal assembly, and master cylinder piston. As you can see in one of our photos, the steering column hangs from the inside brow on the firewall with some custom-made square tubes. The column shaft is guided through the firewall through a swiveling collar bearing. Installation of the inside column was easy.

Step 13: Dash Board

With the steering wheel installed, and the pedals installed, it was time to finish the structural installation of the dash board. We notched the fiberglass ends of the instrument panel to fit over the brow. We also used 1/4" weld metal straps from the panel to the square tubing on the steering column to stiffen the assembly. This panel then slipped over the brow and we used small machine screws and metal tabs to attached it. We then used some hole saws to drill-out the openings for our gauges.

We purchased premium electrical Auto Meter gauges with black faces and chrome bezels. The theme of our truck is black and chrome. Besides the standard oil pressure, water temp, speedo and fuel gauge, we added a clock, ammeter and tach. The balance of the dash board installation and wiring was planned for later in the project.

Step 14: Shifters

This installation was fun and relatively easy. We simply followed the instructions for the B&M Hammer Shifter. The instructions were very easy to follow. The biggest part of the installation was determining the shifter location. That being done, the whole installation took us about 2-hours.

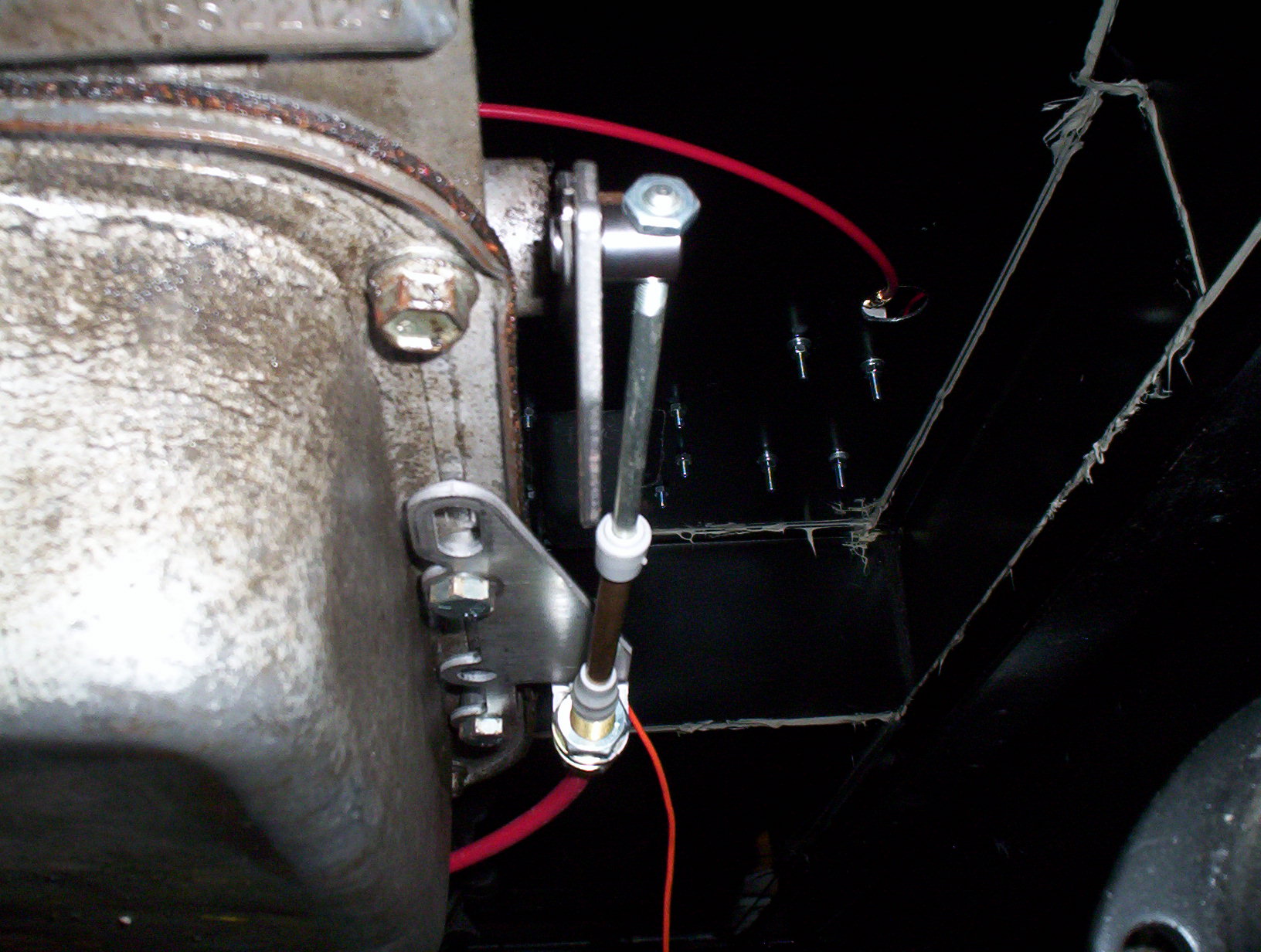

Next - We wanted to have the transfer case shifter right next to the transmission shifter. This prooved easy. We bought pillow-block bearings, a 5/8" shaft, and designed linkage arms that put our transfer case shifter right where we wanted it. This was another easy assembly, but we took our time in getting the right throw-length and linkage angles to guarantee smooth shifting. We then modified the donor's transfer case shift cover, cut it down to size to marry-up next to the B&M shifter cover. You can tell they aren't companion covers, but they are both black and functional, and hopefully, no one will pay attention because the rest of the truck will look and drive like a beast.